A house is only as strong as its foundation, and this is especially true for an adventure vehicle like an Outside Van. However, unlike a normal house, we need to account for constant movement and road safety when building and installing our conversions.

When we get bare van chassis from the factory, there is a substantial amount of work needed to prepare the chassis to accept a van conversion that is durable, comfortable, and free from rattles and damage from adventurous use. This includes adding an infrastructure for all the conversion components to attach to, insulation, wiring, and incorporating specialized building techniques. In this article we will go over what we do behind the walls to get a van ready and up to the standards of an Outside Van.

INFRASTRUCTURE

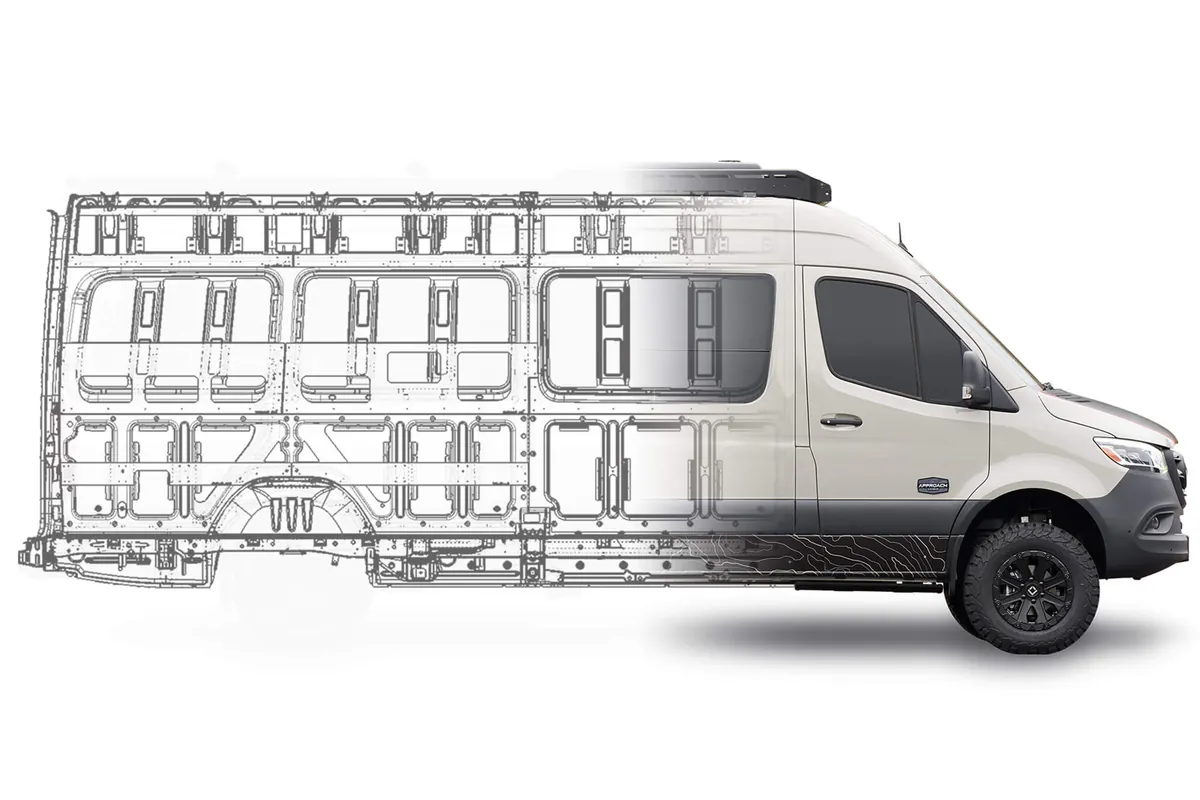

On every van, the first component we add in a reinforced infrastructure that covers the walls and ceiling. Adding infrastructure for interior components to be secured to is a crucial step in safety and durability in every vehicle conversion.

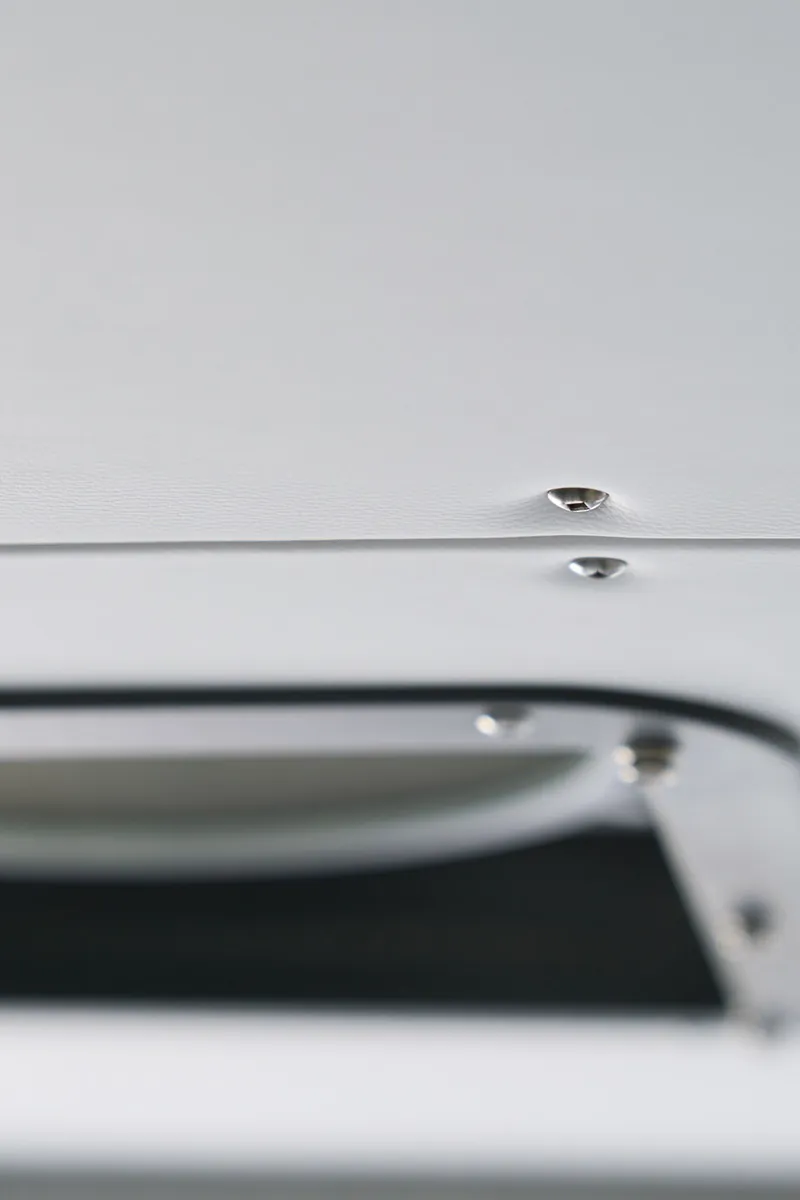

Our infrastructure consists of 16 and 14-gauge galvanized steel panels that are strategically attached onto the bare chassis. We use existing mounting points to minimize permanent modification to the chassis, and place the infrastructure panels in areas that will need reinforcement when the conversion is installed. Each panel is precision cut to optimize space and weight, and designed for a specific task. For example, the infrastructure panels used behind the galley are shaped and placed specifically for a galley to be secured.

PRE-WIRE & INSULATION

PRE-WIRE

It is essential to run wiring before components are installed. We use existing wire chases to meticulously route all our main wiring. To protect the wires, we coat the bare chassis metal with a rubber coating that will prevent fraying from the natural movement caused by vehicles on the move. You will not find a “rat’s nest” of wires in an Outside Van, we take immense pride and dedication in making our routing neat and organized so that in the off-chance service is needed behind the walls, the issue can be addressed quickly, efficiently, and preventing unnecessary damage and costs caused by sloppy wiring.

INSULATION

Before the walls go up, we pack every cavity with mold-resistant synthetic insulation to help maintain and regulate interior van temperatures. We first concentrate on the walls and ceiling, and use black-backed 3M Thinsulate sheets that we cut on a CNC to precisely fit each cavity. The insulation is then packed and adhered using a strong spray adhesive to ensure no shifting over time.

WALLS, CEILING, & FLOORING

WALLS & CEILING

The walls of all our models are precision cut and wrapped in proven durable materials to provide a cozy and long lasting interior. First, we CNC cut multiple wooden panels to cover the walls and ceiling of the van. We then apply a thin layer of foam insulation to soften the surfaces which helps prevent damage to the surface materials and helps with sound dampening inside the van. Finally, we wrap each panel with a durable surface material such as Interweave or Sileather.

Featured on every van, Interweave performance fabric is non-allergenic, mildew resistant, and won’t absorb spills or stains. It’s extremely durable and holds up to regular heavy use. A staple in Outside Vans from the beginning, Interweave is tested and approved!

On select models like Approach, we also incorporate Sileather. Sileather is a silicone leather that’s easy to clean, weatherproof, antimicrobial, and highly durable. Silicone has high thermal stability due to its molecular bonding, which means it’s resistant to both low and high temperatures, which vans see a lot of. Because of its low surface tension, it’s stain resistant and hydrophobic.

FLOORING

The core to our floor is a 3/4 inch marine-grade plywood. Marine grade plywood is constructed specifically to resist environments that have rapid humidity changes which prevents warping which further helps ensuring longevity of the conversion. First we apply a layer of foam to the bare chassis floor. This provides an even surface for the plywood floor to sit on, as well as acts as a thermal and sound barrier.

On Approach and Syncline, we wrap the floor with Lonseal Lonridge Vinyl flooring.This durable marine grade vinyl can withstand the most rugged adventures and can be easily wiped down when its time to clean up sand, dirt, mud, snow, or pet hair. Boasting a unique cross-hatch embossed design, Lonseal Lonridge flooring has all the slip resistance a surface needs while also providing a dusting of speckles that help mask the mess.

On Parks, we use a woven synthetic material from 2tec2 which is not only durable and easy to clean, but is a comfortable surface is ideal to kick the shoes off and go barefoot after a fulfilling day exploring the outdoors.

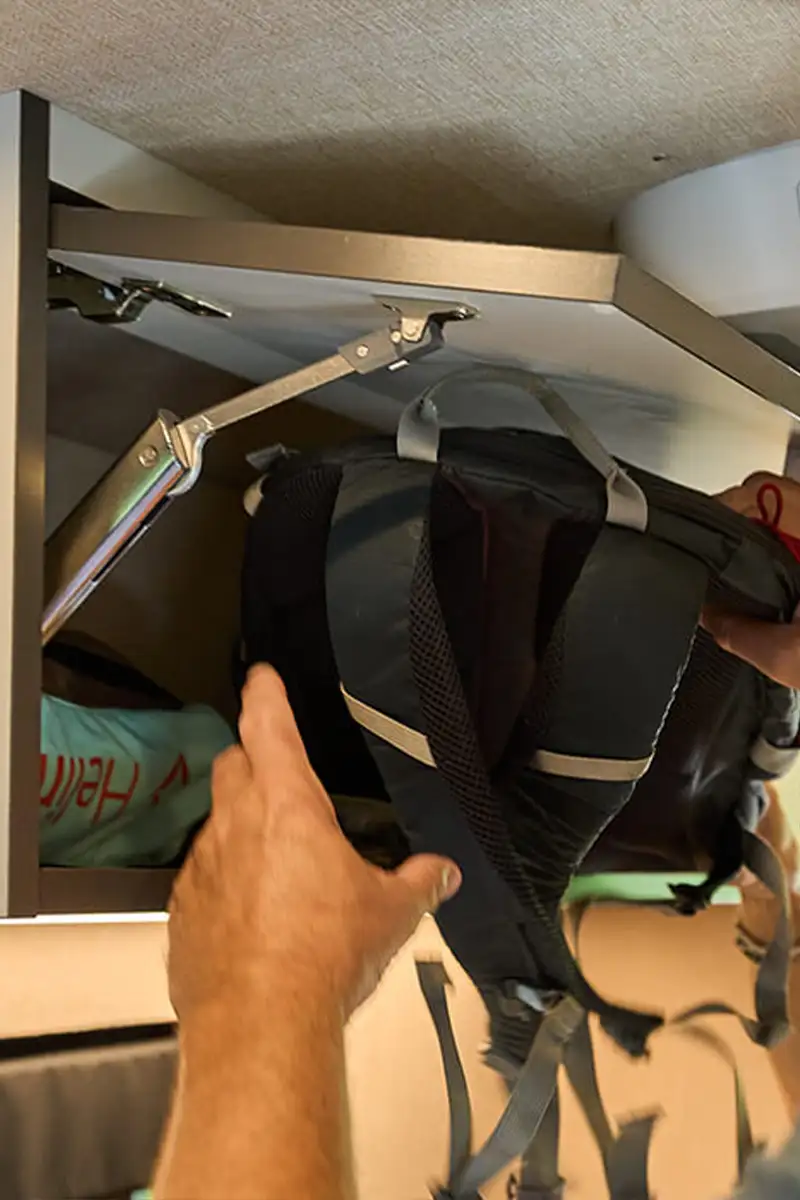

CABINETRY

You won’t find any particle board here. Known for its water resistance, strength, dimensional stability, and longevity, we use marine grade plywood for all of the cabinetry found in our models. Our cabinet shop has its roots in the yacht industry and incorporates specialized construction techniques such as dovetail joints to make the cabinetry extremely strong and up for anything you can throw at it!

These are some of the core features incorporated into our vehicles that most people do not get to see. By focusing on the infrastructure, we can ensure a experience that only an Outside Van can deliver.